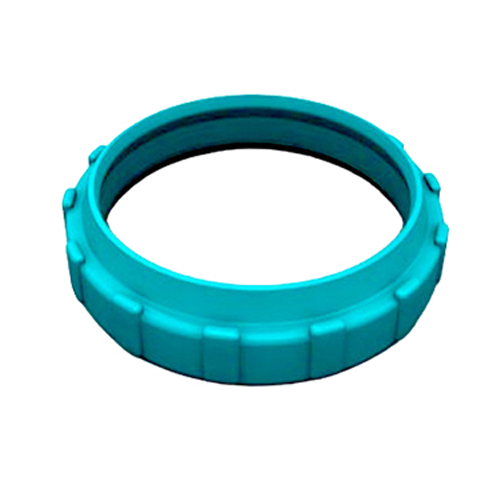

Cushioning Seals

Pneumatic cylinders have cushioning seals that provide controlled final position retardation. As the final position is neared, tapered sleeves, which are firmly attached to the piston rod, gradually close the passage towards the line connection of the cylinder. A needle valve controls the diffluent medium.

This valve can be adjusted to control the stroke movement delay. The cushioning seal designs are non-returnable and provide free flow. we provide robust seal profiles suitable for harsh operating conditions and can withstand extreme wear and high temperatures.