Axial Piston Pump Dealers

Only a few companies are able to make high-grade Axial Piston Pumps. Gs Hydraulic is the Axial Piston Pumps Suppliers.

This article will discuss the benefits of Axial Piston Pumps.

We'll then go into the details.

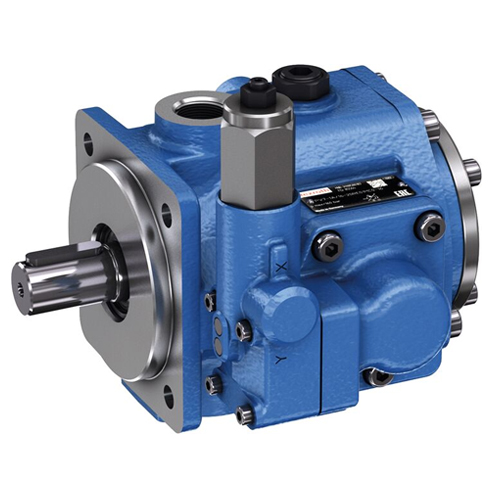

What are Axial Piston Pumps?

Axial Piston Pumps are engineered to maximize efficiency in the field of pumping. They are engineered to be affordable yet with high-quality construction. The pumps are constructed with solid frames and cast iron covers that ensure long-lasting performance. The pistons are engineered for smooth operation and are simple to clean, providing the pumps with a long lifetime. The pumps can deliver a flow rate that can reach 250gallons every minute, similar to other pumps available. The pumps are available in four sizes that include 3/4", 1-1/2", 1" and", 3/4", 1", and 1-1/2".

They are also able to operate at maximum pressurization of 1,200psi. An axial Piston Pump is a pump developed to create a difference in pressure between the outlet and the inlet. It is a pump that creates pressure differences between the inlet and outlet. Axial Piston Pump features an impressive power-to-weight ratio and can operate against pressure as high as 60 bar. This Axial Piston Pump comes in double- and single-acting models. These pumps are reliable and easy to use, making them ideal for high-pressure applications requiring a liquid supply.

Note:G.S. Hydraulics is the best Axial Piston Pumps Supplier. We sell these Axial Piston Pumps at the lowest price.

Different Kinds of Axial Piston Pumps?

Two axial piston pumps, pneumatic and hydraulic, are utilized for similar tasks. Hydraulic pump A hydraulic pump is the most commonly used pressure pump. These axial piston pumps use a tiny volume of oil to move around. Hydraulic pumps are found in reservoirs, tanks, and large displacement pumps. They are utilized for the pumping of liquids. Pneumatic Pump: They use the pressure of air to propel them around.

There are a variety of pneumatics pumps, including turbines, compressors, pumps, and fans. Pneumatic pumps are used in machines that require a pneumatic function, like turbines and compressors. The pistons of Axial piston pumps function as the primary moving components that make up the pumps. They are made of ceramics, metals, and nonmetal elements.

Variable Displacement Axial Piston Pump

The variable displacement Axial Piston Pump is the most commonly utilized positive displacement pump. It is used for various purposes, such as pumping liquids, slurry, and other viscous substances. It operates at a wide range of flow rates and pressures. This kind of pump is perfect for handling fluids with various viscosities. It has high performance, low noise, and is highly reliable. The pump operates in a wide range of flow rates and pressures. The Variable Displacement Piston Pump can handle large quantities of fluid. It has high efficiency, is quiet, and is reliable. The variable displacement axial piston pump is one pressure pump utilized in various applications.

This pump is used for numerous applications, including oil and water production, wastewater treatment, and food processing. The variable displacement Axial piston pump (VDAP) is the most commonly used pump. It has been a vital element in the modern process of industrialization from the beginning. The VDAP is widely used due to its economic and safety efficiency and highly robust reliability. It is well-known that VDAPs are employed in producing water, oil, and refinery processes.

Axial Piston Pumps Function

Axial Piston Pumps Function uses a long cylindrical device with an internal piston. The piston is connected to a rod connected to either a motor or an electric motor. It is driven to move upwards and downwards through the rod and its movement. The upward and downward motion results in a pumping effect. These pumps are usually employed within the food and drink industry to move water and other fluids. This is due to their ability to deliver an uninterrupted stream of liquid.

The fluid being pumped does not need to be pressure-controlled. This creates it more accessible for pumps to work. Axial Piston Pumps can also be employed in the gas and oil industry to move gas, oil, and other fluids. It is due to their capacity to supply an uninterrupted stream of fluid. The liquid being pumped doesn't have to be pressure-controlled. This makes it much easier for the pumps to function.

Note:G.S. Hydraulics is the best Axial piston pump Dealers.

Difference Between Axial and Radial Piston Pump

The Axial piston pump is one type of pump that uses aligned pistons to produce a pressure difference between both faces of the piston. It has been modified for various industries, including power generation. Axial piston pumps have numerous advantages over other kinds of pumps. One of them is that it can operate at very high pressures.

It can, for instance, be used at pressures up to 10000 psi. Additionally, it has a slow speed and can take on vast quantities of liquid. This pump is secure because it doesn't use seals, bearings, or any other damaged or worn-out mechanical components. The Axial piston pump is primarily employed in the gas and oil industry to transfer liquids into pipelines.

Axial Piston Pumps Advantages

The Axial piston pump is a practical, affordable, durable, and cost-effective method of moving liquid. These pumps have been employed for a long time and utilized in various industries. They are most frequently used in the chemical sector and for the manufacturing of drugs. Axial piston pumps can achieve this because they are axial flow pumps. The Axial piston pump is secure because it does not require seals from outside. This means there is no maintenance needed for this kind of pump. The Axial piston pump is efficient because it doesn't require external seals. This is a very efficient method to move liquids since it does not require seals, packing, or sealing. This means that there's less maintenance needed for this kind of pump.

The Axial piston pump is a cost-effective, efficient, and reliable method of transferring liquid. They are made to offer the best solution to your water pressure requirements. This product will stay a longer time and can aid in saving money. These pumps are made of a highly durable, rust-proof material. These pumps can withstand wear and tear and will not disintegrate like other items. If you purchase an Axial Piston Pump, you get a product protected by a manufacturer's guarantee. If you enclose any problems regarding this product, you can contact the company Called Gs Hydraulic. We are the best Axial Piston Pump Supplier.

Axial Piston Pumps Applications

The Axial piston pump can handle large amounts of gas or liquid. It is used for situations where the fluid must be moved swiftly, for example, in agriculture applications. They are also utilized in the gas and oil industry.

This kind of pump is used in the irrigation system, exploration for oil and gas, and nuclear power plants. Axial Piston Pumps are utilized across various industries but are essential for the food and drink industry. Piston pumps are commonly used to move chemicals, sewage, water, and other fluids.

Why Choose Gs Hydraulic?

We are the best Axial Piston Pump Suppliers and Dealers in Mumbai, Maharashtra, India. Gs Hydraulic makes any company's hydraulic cylinders, pumps, and attachments. We are known for making pumps and other Hydraulic products. We have a team working hard to improve their products and services.

Gs Hydraulic makes hydraulic pumps, valves, fittings, External Gear Pumps, etc. Our products are used all over the world in many different industries. We make things that speed up and make your work easier. Gs Hydraulic creates, causes, and sells high-quality hydraulic systems used in product development. We sell out these Axial Piston Pumps for Sale at a low price. Hence, we are the best Axial Piston Pump Supplier.